|

制氢

|

制氢

|

制氢

|

制氢

来源:惠生工程

时间:2025-06-12

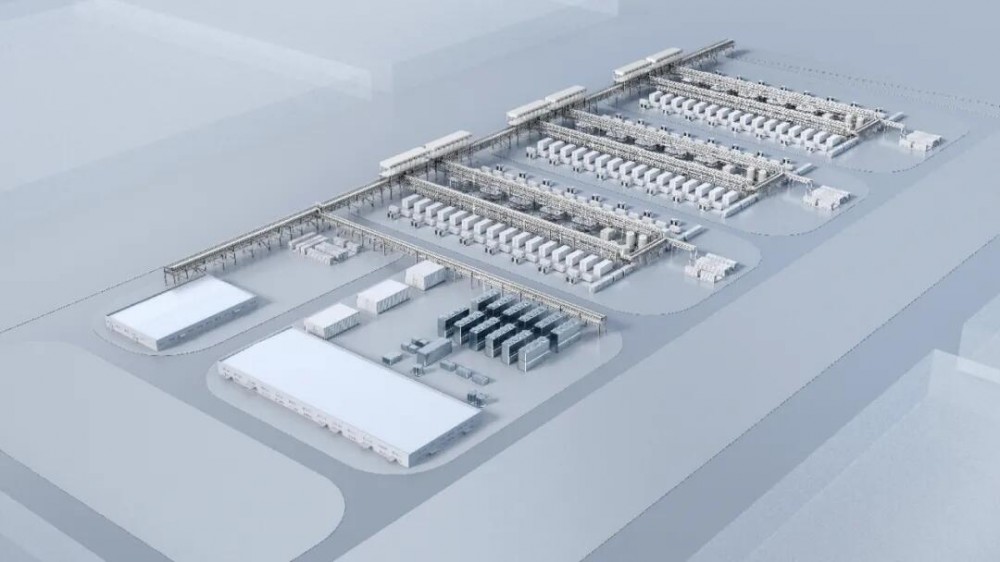

2025年6月11日,全球领先的能源工程EPC服务与技术整合方案提供商惠生工程,携手专注于水电解制氢技术的阳光氢能,正式发布面向大规模绿氢生产的一站式整体解决方案——MegaFlex。这一解决方案基于“工厂即产品”的理念,将绿氢工厂从传统工程项目转变为可复制、易扩展、快速部署的工业产品,显著提升交付效率,实现更优化的平准化绿氢成本。发布仪式在上海2025 SNEC国际光伏与智慧能源大会期间举行。

On June 11, 2025, Wison Engineering, a global leader in energy engineering EPC services and technology integration, partnered with Sungrow Hydrogen, a specialist in water electrolysis hydrogen production technology, to officially launch MegaFlex – a comprehensive, large-scale turnkey solution for green hydrogen production. Based on the "Plant-as-a-Product" concept, MegaFlex transforms traditional green hydrogen plants into replicable, scalable, and rapidly deployable industrial products, significantly improving delivery efficiency and optimizing the levelized cost of green hydrogen (LCOH). The launch ceremony took place during the 2025 SNEC International Photovoltaic Power Generation and Smart Energy Conference in Shanghai.

此次发布,是双方于今年5月签署战略合作协议后达成的重要阶段成果。双方将围绕绿氢工程的标准化路径开展深度协作,涵盖方案设计、系统集成、模块制造到现场交付的全过程。惠生工程在模块化研发、设计、交付,供应链执行和全球项目管理方面经验丰富,阳光氢能在制氢全流程研发、绿氢项目实施方面拥有扎实实力,双方优势互补,共同构建面向全球市场的高效绿氢解决方案。

This launch marks a key milestone following the strategic cooperation agreement signed by both parties in May 2025. The collaboration focuses on standardizing green hydrogen engineering, covering the entire process from design and system integration to modular manufacturing and on-site delivery. Leveraging Wison Engineering’s expertise in modular R&D, design, delivery, supply chain execution, and global project management, alongside Sungrow Hydrogen’s proven capabilities in full-process R&D and green hydrogen project implementation, the partnership combines complementary strengths to deliver efficient green hydrogen solutions for global markets.

MegaFlex 核心亮点:

MegaFlex Key Highlights:

1、成熟可靠的柔性电解制氢技术,智能电解槽数字化管理系统,拥有国际化工程能力,技术领先,性能安全可靠。

1. Proven Flexible Water Electrolysis Tech – Safe, reliable hydrogen production with smart digital management and global engineering expertise.

2、标准化设计,提供覆盖不同规模制氢场站的一站式解决方案,支持快速部署与灵活扩展。

2. Scalable & Fast Deployment – Standardized designs for all project sizes, enabling quick setup and easy expansion.

3、模块化交付,显著降低现场施工成本与风险,提升项目整体交付效率。

3. Modular & Cost-Efficient – Reduces on-site risks, on-site construction costs, and accelerates delivery for faster ROI.

MegaFlex设计结合了Mega+Flex的设计理念,Mega代表单套系统具备500MW级制氢能力,Flex体现方案的高度兼容性,既可向上拓展至吉瓦级工程,也可向下适配几十兆瓦的中小规模项目,满足不同阶段的绿氢开发需求。此外系统还集成了惠生自主研发的智能仿真平台RelPS,可根据风光资源、下游负荷与运行需求进行配置优化与控制策略调整,优化初始投资与运行成本。

The MegaFlex design combines the "Mega+Flex" design concepts - where "Mega" represents its industry-leading 500MW single-unit hydrogen production capacity, while "Flex" demonstrates the solution's exceptional adaptability to scale up to GW-level projects or down to medium/small-scale applications, meeting diverse green hydrogen development needs across different phases. The integrated Wison-developed RelPS intelligent simulation platform further enhances the system by optimizing configurations and control strategies based on renewable energy inputs, downstream load demands, and operational requirements, effectively reducing both initial investments and operating costs.

在发布仪式上,双方对方案的成功发布表示热烈祝贺,并对未来的持续合作充满期待。惠生工程首席技术官刘恒伟先生表示:"阳光氢能在水电解制氢方面具备深厚积累和卓越表现。此次强强联合,不仅是惠生工程在绿氢工程化领域的重要实践,也是我们新能源工程服务能力持续提升的体现。通过融合‘工厂即产品’理念下的模块化设计与标准化交付,MegaFlex 将为全球客户提供更安全、更高效、更经济的绿色氢能解决方案。"

At the launch ceremony, both parties celebrated the successful debut of MegaFlex and expressed enthusiasm for future collaboration. Mr. Liu Hengwei, CTO of Wison Engineering, stated: "Sungrow Hydrogen brings profound expertise and outstanding performance in electrolysis technology. This partnership not only represents a significant step in Wison Engineering’s green hydrogen engineering capabilities but also underscores our commitment to advancing renewable energy solutions. By combining modular design and standardized delivery under the ‘Plant-as-a-Product’ philosophy, MegaFlex will provide global clients with safer, more efficient, and cost-competitive green hydrogen solutions."

绿氢作为绿氨、绿醇等可持续燃料的重要原料,正逐步成为能源转型的核心环节。随着全球对可持续航空燃料(SAF)及绿色合成燃料需求持续增长,以及碳减排政策与环保标准趋严,惠生工程希望通过此次合作,进一步提升在绿氢领域的技术工程化能力,助力推动全球氢能发展与能源结构深度转型。

As a critical feedstock for sustainable fuels like green ammonia and green methanol, green hydrogen is becoming pivotal to the global energy transition. With rising demand for sustainable aviation fuel (SAF) and synthetic green fuels, coupled with tightening carbon policies and environmental standards, Wison Engineering aims to further strengthen its hydrogen technology engineering capabilities through this collaboration, driving the global hydrogen economy and the transformation of energy systems.

关于 惠生工程

About Wison Engineering Ltd.

惠生工程致力于成为全球卓越的环境友好服务商,专注于石油化工、碳一化工、炼油、新能源、新材料等领域的技术和工程建设服务。从技术许可、项目融资、工程前期的策划、咨询到设计、采购、施工管理、开车直到运营服务,惠生工程可为境内外客户提供覆盖项目全生命周期的技术和工程整体解决方案。

Wison Engineering Ltd. is committed to becoming a leading environmentally friendly service provider, specializing in technology and engineering construction services across petrochemical, syngas chemical, refinery, new energy, and advanced materials. Wison Engineering offers comprehensive technical and engineering lifecycle solutions for clients worldwide, from technology licensing and project financing to early-stage planning, consulting, design, procurement, construction management, commissioning, and operational services.

关于 阳光氢能科技有限公司

About SUNGROW HYDROGEN SCI&TECH. CO., LTD

阳光氢能科技有限公司是阳光电源(股票代码:300274)子公司,专注于水电解制氢技术的研究,主要产品有碱性水电解槽、PEM 电解槽、电解槽数字化管理系统、PWM 制氢电源、气液分离与纯化设备、智慧氢能管理系统,致力于提供“高效、智慧、安全”的可再生能源柔性制氢系统解决方案。

As a subsidiary of Sungrow (Stock Code: 300274), Sungrow Hydrogen specializes in water electrolysis technology for hydrogen production. Its main products include ALK electrolyzers, PEM electrolyzers, PWM hydrogen production power supplies, gas-liquid separation equipment, hydrogen purification equipment, and intelligent hydrogen management system. Sungrow Hydrogen is committed to providing "efficient, intelligent, safe" flexible green hydrogen production system solutions.

国际氢能网声明:本文仅代表作者本人观点,与国际氢能网无关,文章内容仅供参考。凡注明“来源:国际氢能网”的所有作品,版权均属于国际氢能网,转载时请署名来源。

本网转载自合作媒体或其它网站的信息,登载此文出于传递更多信息之目的,并不意味着赞同其观点或证实其描述。如因作品内容、版权和其它问题请及时与本网联系。

![]() 图片正在生成中...

图片正在生成中...